Contact Information

Telephone:+8618538825566

Telephone:+8615670305588

E-mail:lyrxskj@163.com

Address: No.16, Senlan Road, Changbaozhen, Mengjin District, Luoyang City

Aluminum shell furnace body 2 tons

- Commodity name: Aluminum shell furnace body 2 tons

Product Details

Application

Mainly used for smelting cast iron, stainless steel, alloy steel, non-ferrous metals, including heavy metals (such as copper, lead) and precious metals (such as gold, silver), etc. The equipment is used in metallurgical industry, casting industry, non-metal smelting and other industries.

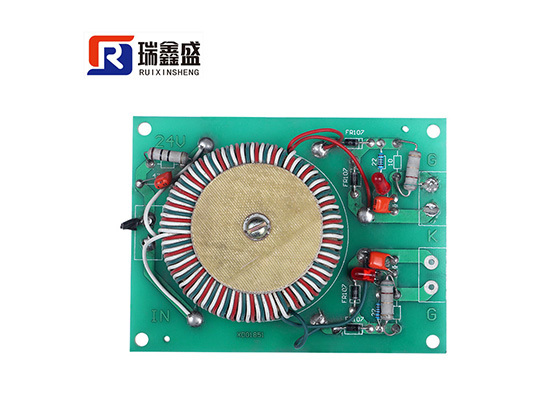

Aluminum shell

Adopting reduction gears tilting furnace device. The furnace body is made of alloy aluminum foundry casting. Simple operation, easy maintenance, convenient observation.

The aluminum shell furnace is composed of reduction gears, bracket and induction coil, etc. Mainly used for smelting cast iron, stainless steel, alloy steel, non-ferrous metals, including heavy metals (such as copper, lead) and precious metals (such as gold, silver), etc. The equipment is used in metallurgical industry, casting industry, non - metal smelting and other industries.

Products advantage

1. Good stability, low cost, smaller area occupied.

2. Easy to operate, fast melting and low production cost.

3. Simple structure, easy maintenance.

4. Can be directly melted from the cold furnace, solution can be all empty, easy to replace the type of molten material.

5. Low noise, good working environment.

6. Tailor-made according to the different melting metal.

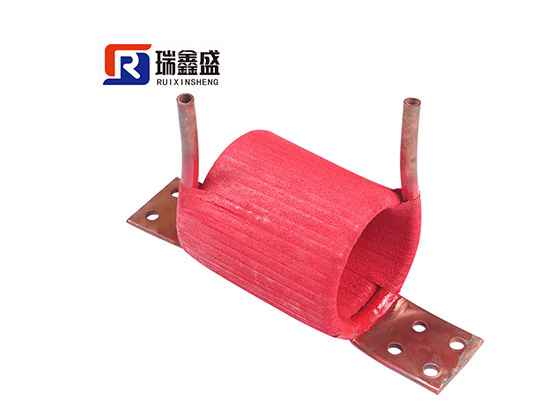

7. Induction coil of various specifications, reasonable selection of copper tube wall thickness and specifications, so as to improve the utilization rate of electrical energy.

8. High performance insulation materials are used.

9. The turn-to-turn gap of the induction coil is convenient for maintenance and conductive to the release of water vapor.

Smoke collecting device can be used to improve working environment.

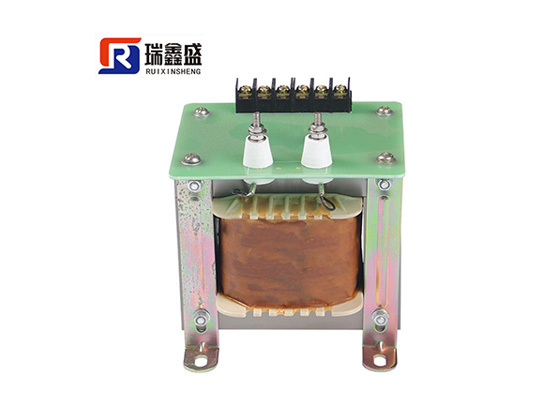

Power Supply

This melting furnace can realize fully automatic remote control, including PLC programmable controller, HMI man-machine interface or industrial control computer system, industrial control configuration software and various sensors. It can realize automatic operation, such as automatic constant temperature, automatic oven and furnace leakage alarm, which is safer and more convenient to use.

The power advantage

1. Through a single power supply device, realize the mass production capacity of multiple furnaces.

2. Uninterruptible melting and accurate thermal insulation or overheat temperature control.

3. It can preheat, sintering, melting and ultra-low power insulation for multiple electric furnaces at the same time.

4. Each furnace adopts independent control system.

5. Can provide full constant power to one furnace while isolating the other under maintenance.

6. Just one set of power connection and water connection, greatly reducing installation, operation and maintenance costs.

7. The latest generation of digital operation technology, Single Clip Microcomputer program control.

8. Lower starting frequency, ultra-low power oven.

9. Full open rectifier, high power factor, Higher harmonics are small.

10. The equipment power utilization rate is close to 100%.

11. Liquid metal is more productive and does not need to increase electricity demand.

12. It can produce efficiently and match different metal liquid demand levels.

13. Optical fiber transmission trigger signal, electronic control using digital mode.

14. Very competitive power consumption indicator.

15. Comply with domestic and international electrical safety design standards.

16. More perfect and intelligent protection function.

Key words:

Aluminum shell furnace body 2 tons